Written by Cordell Clouston

As 2021 begins, we put behind us a year that saw the world turn upside down. Many of us were stuck inside our homes, missing the people we loved, and unable to do the things we enjoyed. However, time continued to move forward, innovations continued to be made, and new regulations continued to sweep through local legislature and Congress. Now is the time to look in the future as we start the New Year. As engineers and construction managers, we must be aware of the new technologies, market growths, and procedures affecting our industry. While listing everything that is changing could never fit onto a five-minute blog, here a few of the innovations I see to be incredibly impactful within the next decade.

As technology progresses, surveying is starting to go through a metamorphosis. The “boots on the ground” surveying is beginning to fade away as a new technology progress. LiDAR, or Light Detection and Ranging, is a method utilizing lasers to measure ranges and then uses that data to produce incredibly accurate, 3D information about an area. One day of work with a single LiDAR rig can be the equivalent of multiple weeks worth of surveying. By 2027, the LiDAR industry will grow over 2.9 billion dollars and continue to grow in use from there. But what applications can you use LiDAR for, and what is the best way to use the system?

LiDAR’s topographic abilities allow for use in a diverse variety. For engineering purposes, LiDAR can make a 3D projection of a city’s infrastructure, which benefits the engineers by to better design future civil and structural projects. LiDAR will also help accurately tell the cost of building on any land by showing the area’s conditions, connection to already in place utilities, and help generate an understanding of what tools are needed for a project. In construction, LiDAR is not just used in surveying an area, but can be used at any step in the construction process to ensure the project is in ideal conditions and follow all guidelines; all put into an easy to see 3D representation. For forestation and mountains, it can be used to scope a mountain and accurately tell not only the slope of the range but also give an estimate of the biodiversity of life in an area. In places like California and Colorado, they can accurately show the damage caused by forest fires without putting surveyors at risk in the regions with new dangers from the dead trees, hidden holes, or other hazards. Essentially, LiDAR does what surveyors do but in less time.

LiDAR is easily implemented by mounting onto tripods or cars, but the fastest-growing use of LiDAR is through aerial surveys. Ariel LiDAR is done by attaching a LiDAR system to a flying object and scanning an area or structure. The most used Ariel LiDAR is with drones, and companies like Phoenix Lidar and Lidar USA have made some fantastic LiDAR systems that can easily show an area. However, drones are frequently placed under new restrictions as drones become more popular for commercial use, and drones only have an average flight time of around 20 minutes. To have an extensive ariel survey done, you will need to attach the LiDAR system to either a plane or helicopter. With Helicopters being able to fly anywhere from 2.5 and 5 hours, you could see hundreds of miles and thousands of acres of surveyed in a single flight!

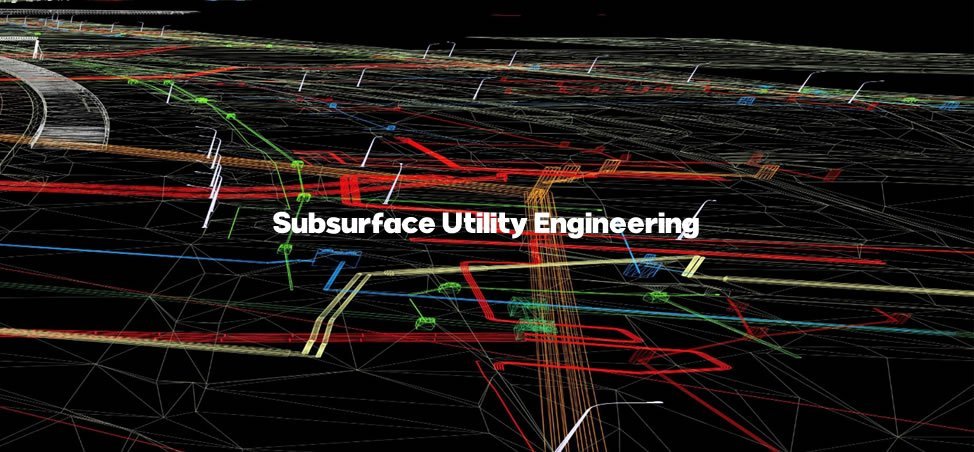

A specific type of engineering that is growing increasingly popular by states and different organizations is using Subsurface Utility Engineering (SUE) for design work on projects. In 2020, Colorado passed a law that any engineering and construction project will have to have SUE work done before the project starts. On top of that, almost every State’s DOT use SUE to make sure they know what underground utilities will be impeding their work. With the US spending a projected 34.35 billion on “smart cities,” SUE is expected to grow in the states at a rate of 9.5% annually. But what is SUE, and how is it being used?

Subsurface Utility Engineering is the tracking of underground utilities and then mapping those utilities for customers. These utilities can include something as small as underground wires to massive sewers systems and pipelines. SUE’s job is to aid in the design work engineers and architects to ensure the inclusion of any utilities, or lack of utilities, that may be in the project. Now SUE work is not the same as Locating, and some projects will have to have both types of underground surveying done to complete the project. Before you start your next project, see if Subsurface Utility Engineering could useful or is mandated by your local authorities.

Since the 1990s, the United States has made tens of millions of new buildings and the average floor sizes of these buildings is growing by the year. Only looking at commercial buildings, the amount of floor space used has grown from about 70 billion at that time square feet to almost 100 billion in 2018. With the increase in buildings and increase in size, new technology is needed to create and maintain the increasingly larger structures being built every day.

One of the great discoveries of the end of the 2010s was the discovery of self-healing concrete. This product created by companies like Basilisk uses bacteria mixed in with the concrete to produce limestone that seals in cracks in the concrete. The new concrete helps preserve roads, bridges, and buildings’ foundations while also lowering these structures’ upkeep costs. Although the concrete has only been available to use since the end of 2019, the industry is expected to be worth over a billion dollars by 2025. For enormous structures, self-healing concrete could save customers millions by protecting structures from damage and requiring less time spent on maintenance.

Another structural technology that is growing today is Wireless Structural Health Monitoring. Wireless Health Monitoring involves placing Wi-Fi receivers and sensors across a structure that analyzes the assets’ health by looking a variety of factors. This technology is commonly used on large structures like bridges, wind turbines, stadiums, skyscrapers, rock ranges, and other massive objects. The systems helps professionals know what potential problems are happening and what needs to happen to protect the structure. The data is sent back frequently, so when something becomes a problem, engineers and construction companies can create a solution to the problem without the issue going unnoticed for months.

As we enter 2021, going green has become extremely essential to all industries. North America is predicted to become powered by approximately 25% renewable energy by 2030, so the thought of going greener will become more prevalent in consumer’s minds. With 47% of Americans willing to pay more for green products, companies should be thinking about how to create ecofriendly projects to grab more attention. The United States even pushes companies to become more eco-centric by allowing firms to save thousands of dollars in tax credits and deductions just by being eco-friendly. As an engineer, we must be aware of the growing green trend when designing a new project for companies jumping on the eco trend as it will allow us to bring in more customers. Below are some upcoming technologies that may be beneficial to future green projects.

One of the first thoughts companies have when going green is to have solar panels attached to their buildings. But many companies may not realize that wind power is the fastest-growing energy producer globally and has made recent bounds in energy production and has become small enough to use anywhere. Flower Turbines is a small but growing company that makes small and beautiful turbines. Each turbine is only between 3 and 20 feet tall, and they are light enough to be placed anywhere on or around a building. What makes these Flower Turbines special is that they create more power when clustered together, while other wind turbines decrease their output when in proximity due to how they channel airflow. If your project is looking to install a natural energy producer on or near your building, wind power would be an excellent choice to install.

Companies can even go green in the foundation they put into their buildings. Concrete is the most widely used of all construction materials, and some have found a way to mix in large quantities of recycled carbon dioxide (CO2) to clean up greenhouse gasses. Carboncure is the leading producer of this low CO2 concrete and has helped eliminate millions of pounds of CO2. Even better, the concrete mix turns CO2 into Calcium Carbonate (CaCO3), which gets rid of the gas completely. The CaCO3 also makes the concrete around 10% stronger than standard concrete mixes, which helps ease customers minds on the strength of the structures being built. For future construction and engineering works, consider using eco-friendly construction materials in your projects.